|

|

|

상품명

상품명 |

[칩마운터]

BS 684V

4 head |

|

|

제조사

제조사 |

Autotronik-SMT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DETAILS

|

Non-contact Linear Encoder System

By using "Closed Loop" Servo Motors with

non-contact Linear Encoder System, provide extremely high Repeat-ability and

Stability. |

|

Alignment System "Vision on the

Fly"

The

BA281 feature COGNEX® vision processing and head-mounted

for non-contact „Vision on the Fly” alignment. The machine BA385 assures

high-precision placement of the full range of SMDs, from the smallest 0201

devices through CSPs, μBGAs, flip-chips, ultra-fine pitch 0.3mm for QFPs, even

odd-form components. |

|

Strong and rigid

mechanical design

BA684 using welded steel frame which

guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with

Servo Motor system provides high Speed, Repeatability and

Stability. |

|

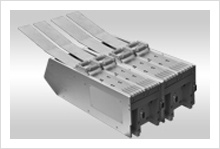

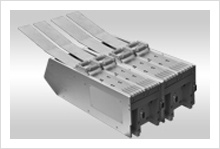

Dual Gantry 4

Heads

With the two rows of dual-heads (4

multi-heads in total), both rows of heads can pick up the components, and place

the components steadily in alternation. The alternating Pick & Place action

eliminates idle time and allows maintain the high-speed

mounting. |

|

Bottom Vision Alignment System (Opt)

A

Bottom Vision Camera is used for large components up to 150 x 100 mm and devices

with alignment features on their bottom side. Due to additional Bottom Vision

Camera, the alignment of 01005 components is

guaranteed. |

|

Smart Fiducial System

Beside the standard fiducial mark, either square SMD

PCB pad or plate-through hole also can be trained as fiducial mark. For more

precise placement of fine pitch components, additional Local fiducial

recognition is provided. |

|

Universal CAD Conversion (opt)

Beside the direct input of data by teach-in camera,

an optional CAD conversion program is available for directly transfer of CAD

generated pick and place data. |

|

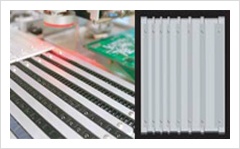

Auto Tape Feeder (KFTA)

The innovative design of KFTA feeder bases and

mounting hardware allows almost limitless flexibility in feeder combinations and

arrangement schemes, as almost every feeder can be ordered, loaded, programmed

and mounted independently. KFTAs are available from 8 mm up to 72 mm tape

width. |

|

Universal IC Tube Feeder

KFTB universal tube feeder are using vibration driven

technique. It is able to handle IC-Sticks with max.50 mm

width. |

|

Cut Strip Tape Holders (Short tape Staion)

Cut Strip Tape Holders is a handy accessory for

present-ing components that are supplied in short lenghts of tape due to their

low quantity of usage. It can also prevent the waste of components in sections

of tape that are too short to be loaded into tape

feeders. |

|

Conveyor System

The already included

conveyor system with SMEMA Interface and motor-driven-width-control speeds up

the handling of PCB and in-line production. |

|

Feeder Rack

(KR-48K)

FR-48K is suitable for

48 x 8 mm KFTA Feeders or for 40 x 8 mm IC-Sticks (2x

KFTB-4). |

|

Buffering Nozzle

The spring buffering design of Nozzle adjust

the placement pressure for different heights of components

automatically

|

|

Vision Inspection

With the built-in software, the camera can

automatically move and display the image in the computer screen. User can

manually check the printing accuracy of solder paste, quality of the soldering,

accuracy of component placement, etc |

|

Remote Service

Kit

Optional Remote Service Kit allows a remote

access to machine by Internet, so that programming, calibration and service can

be done by our worldwide remote service

center. |

| |

|

|

|

|

| SUMMARY |

|

• |

Dual Gantry 4 Heads |

|

• |

Placement rate: up to 10500 CP/H |

|

• |

Conveyor System with SMEMA Interface and Automatic-Width-Control |

|

• |

Non-contact Linear Encoder System for high Repeatability and Stability |

|

•

|

High Accuracy and high Flexibility for 01005, 0201, SOIC, PLCC, BGA,

μBGA, CSP, QFP, up to fine-pitch 0.3mm |

|

•

|

Smart Feeder System provides Automatic feeder Position Checking,

Automatic Component Counting, Production Data Traceability |

|

• |

Perfect for medium and high volume production |

|

• |

COGNEX Alignment System “Vision on the Fly” |

|

• |

Bottom Vision Alignment System for fine pitch QFP & BGA |

|

• |

Built in Camera System with Auto Smart Fiducial Mark Learning |

|

• |

Vision Inspection before and after production |

|

• |

Windows XP Software |

|

• |

Universal CAD Conversion |

|

• |

Ball Screw Systems in X- and Y-Axes |

|

• |

Suitable for 96 intelligent Auto Tape Feeder |

|

• |

Quick change Feeder Trolley |

|

• |

Strong and rigid mechanical design |

|

|

|

|

|

| SPECIFICATION |

|

•

|

Number of Heads (Vision on the Fly): |

BA684V4: 4 |

|

•

|

Placement rate (under the optimum condition): |

BA684V4: 10’500 CP/H (IPC 9850) |

|

•

|

Feeder capacity (8 mm)

with conveyor: |

up to 96 Tape Feeders |

|

•

|

Feeder capacity (8 mm) with conveyer & optional

Feeder Rack Trolley:: |

over 96 Tape Feeders |

|

• |

IC Tray capacity: |

up to 4 Waffle Trays |

|

• |

Component Sense: |

Vision detection |

|

•

|

Component Size:

|

Handled by head camera:

- Smallest: 0.6 x 0.3 mm

- Largest: 16 x 14 mm

Handled by fixed Bottom Vision Camera:

- Smallest: 0.4 x 0.2 mm (option)

- Largest: 150 x 100 mm (option) |

|

•

|

Resolution: |

X / Y axis 0.05 mm Servo Motor

Z axis 0.02 mm Servo Motor |

|

•

|

Rotation:

|

0 to 360° (0.045°/step) Servo Motor |

|

•

|

Placement Accuracy: |

+/- 0.04 mm

+/- 0.03 mm (by optional linear encoder) |

|

• |

X-Y Repeatability: |

+/- 0.01 mm |

|

•

|

Placement Area: |

With included 3-stage-conveyor,

2x 32 port Feeder Rack

Max. 650 x 420 mm (w/o IC-Tray)

Max. 650 x 350 mm (with 1x to 2x IC-Tray)

Max. 650 x 280 mm (with 3x to 4x IC-Tray) |

|

•

|

Programming: |

Direct input

Vision teach-in

CAD Access (Option) |

|

• |

Main Control: |

Industrial PC |

|

•

|

Power: |

240 V / AC - 3810W |

|

• |

Pressure: |

75 psi (5.5 bar) |

|

• |

Machine Size: |

1550 x 1210 x 1430mm |

|

• |

Weight: |

1340 kg |

|

* We reserve the right to make changes without notice |

|

|

|

|

DETAILS

|

Non-contact Linear Encoder System

By using "Closed Loop" Servo Motors with non-contact Linear Encoder System, provide extremely high Repeat-ability and Stability. |

|

Alignment System "Vision on the Fly"

The BA281 feature COGNEX® vision processing and head-mounted for non-contact „Vision on the Fly” alignment. The machine BA385 assures high-precision placement of the full range of SMDs, from the smallest 0201 devices through CSPs, μBGAs, flip-chips, ultra-fine pitch 0.3mm for QFPs, even odd-form components. |

|

Strong and rigid mechanical design

BA684 using welded steel frame which guaranteed a strong and rigid mechanical design. Preloaded Ball Screws with Servo Motor system provides high Speed, Repeatability and Stability. |

|

Dual Gantry 4 Heads

With the two rows of dual-heads (4 multi-heads in total), both rows of heads can pick up the components, and place the components steadily in alternation. The alternating Pick & Place action eliminates idle time and allows maintain the high-speed mounting. |

|

Bottom Vision Alignment System (Opt)

A Bottom Vision Camera is used for large components up to 150 x 100 mm and devices with alignment features on their bottom side. Due to additional Bottom Vision Camera, the alignment of 01005 components is guaranteed. |

|

Smart Fiducial System

Beside the standard fiducial mark, either square SMD PCB pad or plate-through hole also can be trained as fiducial mark. For more precise placement of fine pitch components, additional Local fiducial recognition is provided. |

|

Universal CAD Conversion (opt)

Beside the direct input of data by teach-in camera, an optional CAD conversion program is available for directly transfer of CAD generated pick and place data. |

|

Auto Tape Feeder (KFTA)

The innovative design of KFTA feeder bases and mounting hardware allows almost limitless flexibility in feeder combinations and arrangement schemes, as almost every feeder can be ordered, loaded, programmed and mounted independently. KFTAs are available from 8 mm up to 72 mm tape width. |

|

Universal IC Tube Feeder

KFTB universal tube feeder are using vibration driven technique. It is able to handle IC-Sticks with max.50 mm width. |

|

Cut Strip Tape Holders (Short tape Staion)

Cut Strip Tape Holders is a handy accessory for present-ing components that are supplied in short lenghts of tape due to their low quantity of usage. It can also prevent the waste of components in sections of tape that are too short to be loaded into tape feeders. |

|

Conveyor System

The already included conveyor system with SMEMA Interface and motor-driven-width-control speeds up the handling of PCB and in-line production. |

|

Feeder Rack (KR-48K)

FR-48K is suitable for 48 x 8 mm KFTA Feeders or for 40 x 8 mm IC-Sticks (2x KFTB-4). |

|

Buffering Nozzle

The spring buffering design of Nozzle adjust the placement pressure for different heights of components automatically

|

|

Vision Inspection

With the built-in software, the camera can automatically move and display the image in the computer screen. User can manually check the printing accuracy of solder paste, quality of the soldering, accuracy of component placement, etc |

|

Remote Service Kit

Optional Remote Service Kit allows a remote access to machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center. |

| |

|

|

|

|

|