|

Notice

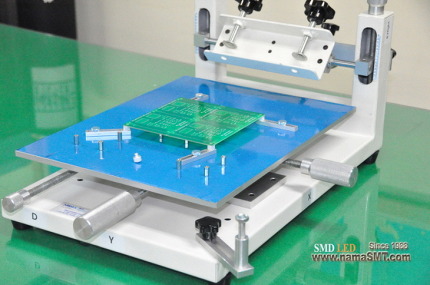

1. Check if the four foot pads cling the ground before operating,to ensure the printer smooth and steady without shaking;

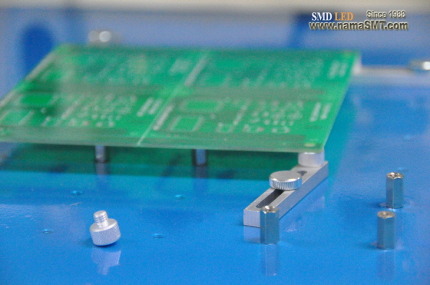

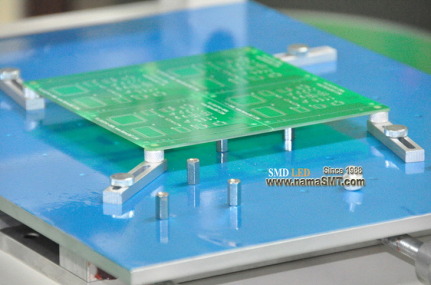

2. Clean all the accessories of platform such as thimble, fixation unit and filler;

3. Confirm the workpiece,PCB boards and steel stencil which need to print;

4. Operate it according to the following instructions step by step after everything has been gotten ready:

Printing

Choose the suitable scraper blade(depends on the width of printing) when printing,keep the screws tight of whole printer(specially note the ones of steel stencil),otherwise it will influence the printing precision.The thickness of solder paste depends on the printing strength,an expert and excellent operator can reach the same effect as the automatic machine,it means the operator is one of the important point for printing quality.The above process is the best experience gain from our engineer and customers during practical using since a long time for your reference.Please kindly inform us if any better process and experience to improve the performance,convenient for customer high-efficiency production.

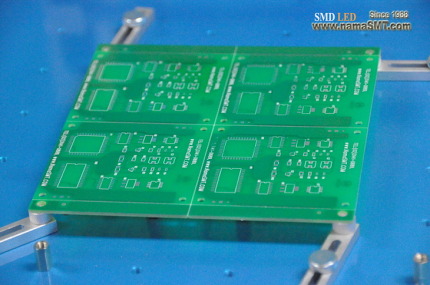

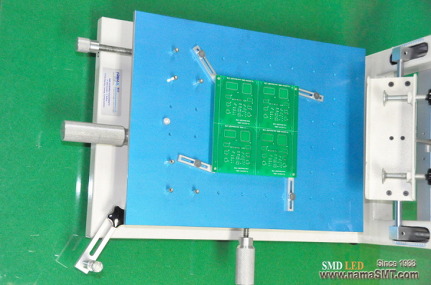

PCB Positioning

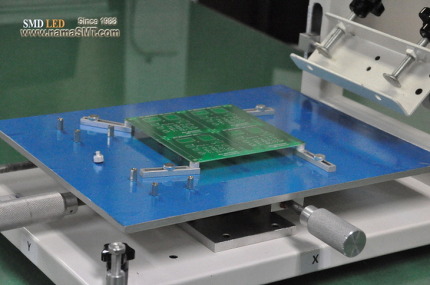

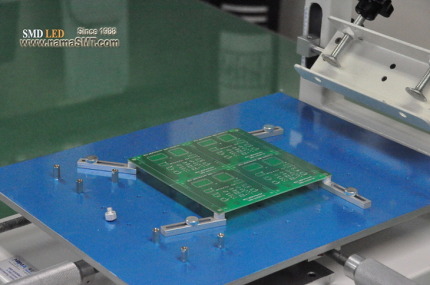

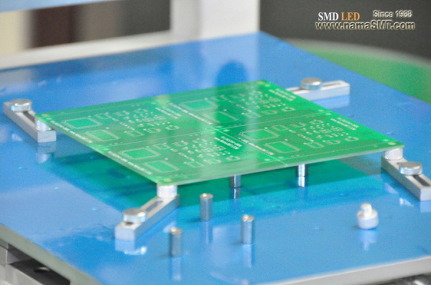

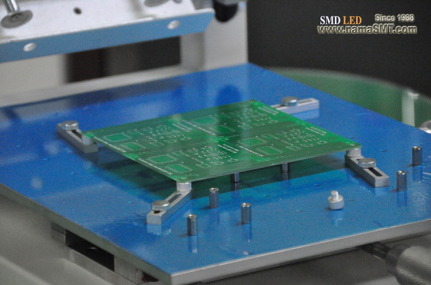

View the position between PCB board and the steel stencil,find out the most suitable position to locate the PCB board on the platform,

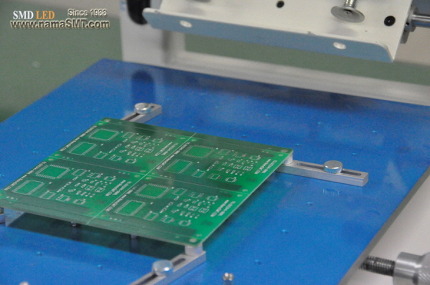

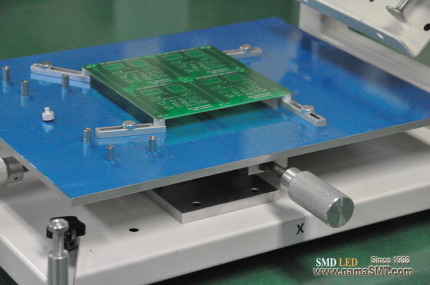

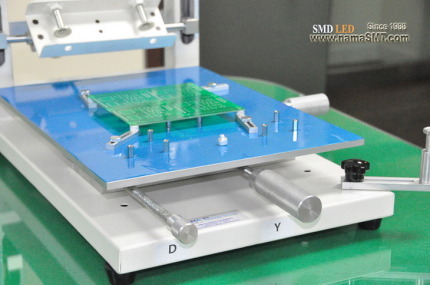

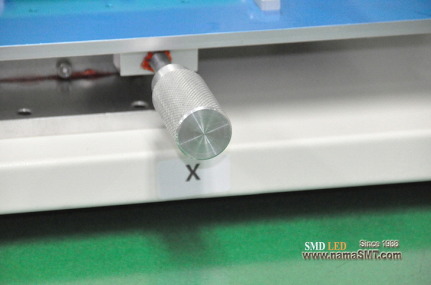

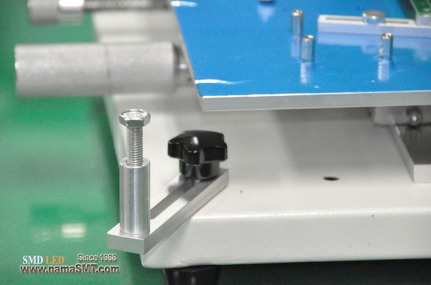

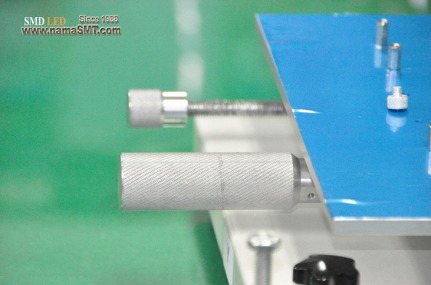

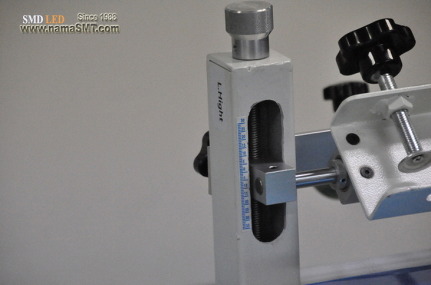

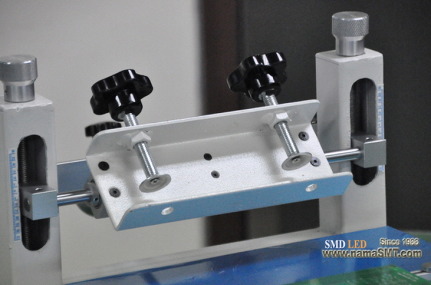

Suggestion:paste a bit double sides adhesive tape to stick the PCB well if the position between PCB and steel stencil confirmed→install the steel stencil on the locating slot of the frame→paste more double sides adhesive tape on the reverse side of PCB board than steel stencil→then pressing the steel stencil→install the filler in the appropriate place between platform and PCB board→adjust the distance between the steel stencil and filler till the same thickness as PCB board(anastomose the PCB and filler),to ensure the PCB board and filler is parallel→tear the paper of double sides adhesive tape which pasted previous on the PCB board→close the steel stencil till the PCB board cement with the filler→lift the steel stencil→the PCB separate from the steel stencil and paste together in the filler of platform→find out the applicable positioning pin and install them into the fixation unit(the height of positioning pin do not exceed the thickness of PCB board)→lock the fixation unit tightly on the platform after positioning pin installed into the fixation unit with fastening,the PCB positioning operation almost finished→adjust the best position between platform and PCB board by using the X-axis adjustment handle and Y-axis adjustment handle

|