|

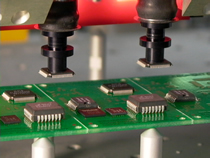

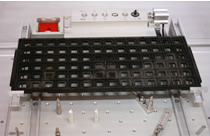

SMT장비 385 1/V2 Max 126 feeder

|

HOME > Products > SMD Pick & Place > 자동 칩마운터

자동 칩마운터 장비 | NamA Since 1988' HOME > Products > SMD Pick & Place > 자동 칩마운터

자동 칩마운터 장비 | NamA Since 1988'

|

|

| uBGA. 0603. 벌크부품.Flip & SCP Chip작업가능 6400 CPH |

|

|

|

|

|

상품명

상품명 |

385 1/V2

Max 126 feeder |

|

|

제조사

제조사 |

AutoTronik-SMT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High Accuracy,High Flexibility for 0201(0.6mmX0.3mm)SOIC,PLCC,BGA, uBGA,CSP,QFP (0.5mm pitch) |

|

Smart Feeder ID Function for speedy Set-up, easy operation |

|

Suitable for small volume production |

|

Vision on the Fly Alignment System |

|

Bottom Vision Alignment System for fine pitch QFP and BGA |

|

Built-in Camera System with auto Fiducial Mark Learning |

|

Dispenser System |

|

Vision Inspection for before or after production |

|

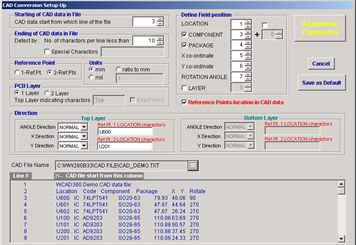

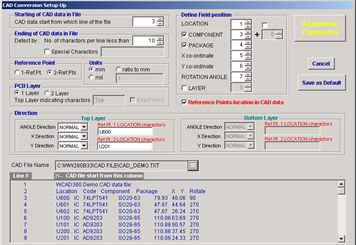

Universal CAD Conversion |

|

Windows 2000 Operation Perform |

|

Ball Screw System |

|

Strong & Rigid Structure

BS384 using heavy duty and high percision linear Ball Rail system to provide strong, rigid and long life time mechanism. |

Ball Screw System

BS383 using pre-loaded ball screw with closed loop DC-Servo motor system, provide high repeatability and stability. |

|

| |

|

Vision on the Fly Alignment System

Vision on the Fly for most SMD components from 0201, SOIC, PLCC & QFP. |

|

|

Dispenser System

With the optional stand alone dispenser head which can dispense adhesive/ solder paste suitable for quick small volume production without making stencil.

|

|

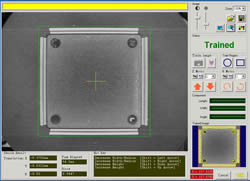

Flexibility Fiducial Mark System

Circular, Square solder pad or even a plated through hole can be use as a fiducial mark for recognition.

|

| Circular solder pad |

square solder pad |

plate-through hole |

|

|

|

|

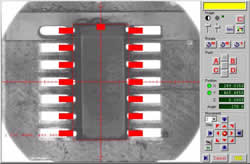

Vision Alignment System

Optional Vision Alignment system for 0.5mm fine pitch QFP, BGA, uBGA & CSP

|

| BGA IC |

QFP IC |

|

|

|

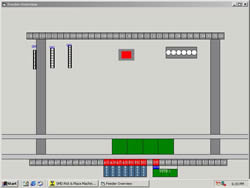

Programme can view

After finished programme, User can view the veracity for Pick&Place

|

| PCB Overlay |

Feeder Overview |

|

|

|

Automatic Tape Feeder:

8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, 72mm tape feeders available for Model BS384

Half step (2mm advance) feeder also available for 0201/0402 component. |

|

Universal IC Tube Feeder:

KFTB universal tube feeder combine with vibration and belt driven technique, provide the best driving for different size ICs at the same time

K FTB-2 (10pcs of 8mm tube)

K FTB-4 (20 pcs of 8mm tube) |

|

Quick Change Feeder Rack:

FR-32K can adapt 32pcs of 8mm tape feeder or 40pcs of 8mm tube feeder |

|

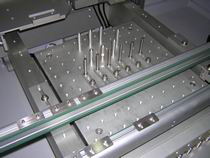

Optional Conveyor System:

With the CY-3V virtual 3 stage conveyor system, which can be speed up the handing of PCB or in-line production. |

|

| |

|

Buffering Nozzle:

Spring buffering design automatic adjust the placement perssure for different height of component. |

|

| |

|

Remote Service Kit

Optional Remote Service Kit provide remote access the machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center.

|

| |

|

Vision Inspection

With the built-in software, the camera can automatically move and display the image in the computer screen, user can manually check the printing accuracy of solder paste, quality of the soldering, accuracy of component placement, etc... |

|

|

Universal CAD Conversion

Beside the direct input of data by teach-in camera. An optional CAD conversion program for directly transfer of CAD generated pick and place data will be available.

| |

|

|

|

|

| |

BS385N-L20 |

BS385V1 |

BS385V2 |

| Max Speed (under optimum condition) |

4000cph |

4000cph |

6400cph |

| No.of Head (Vision on the Fly) |

1 |

1 |

2 |

| Feeder capacity (8/12mm) without conveyor |

up to 128 |

| Feeder capacity (8/12mm) with conveyor |

up to 64 |

| IC Tray capacity |

up to 2 Waffle trays |

| Component Size (mm) |

|

| - smallest |

0.6 x 0.3 |

0.6 X 0.3 |

| - Largest |

20 x 20 |

16 x 14 |

- Largest(option)

(By bottom camera ) |

38 x 38

(SQ Align) |

38 x 38 |

|

48 x 48

(with Option AQ48) |

| Repeat Accuracy |

+/- 0.1mm(Laser Alignment) |

+/- 0.05mm |

|

+/- 0.05mm (Vision Alignment) |

| X-Y Driving System |

Ball Screw with DC Servo Motor |

| Resolution |

X / Y axis 0.0075mm |

|

Z axis 0.02mm(DC Servo Motor) |

| Rotation |

0~360 degree (0.045degree/step DC Servo Motor) |

| Placement Area |

450mm X 350mm ( using 32pcs of Feeders ) |

|

350mm X 320mm ( using 128pcs of Feeders ) |

| Programming |

Vision teach-in |

|

Direct input |

|

CAD Download(Option) |

| Max. Number of Placement Position |

9999 |

| Component Sense |

Vacuum detection / Laser Scan |

Vacuum detection |

| Main Control |

Industrial PC & LCD |

| Machine Size |

1030 X 940 X 1250mm (L x W x H) |

| Weight |

400kg |

| Power |

100/240V,AC |

| Pressure |

75 psi(5.5 bar) | |

|

|

|

|

Inline Conveyer

The SMEMA compatible in-line conveyer system allows the BS381N family to be upgraded for greater throughput, or connecting to a paste printer or reflow oven.

The conveyer can be added later with an easy retrofit.

This protects your investment even with increasing capacity demand. |

|

Board Offset Correction

This sofware package provides automatic datum point recognition of PCBs, which is particularly useful when combined with the inline conveyer system.

For position correction, a mark on the printed circuit board can be used.

In addition, the software also allows bad individual boards, in multiple board arrangements, to be recognized.

The population of these bad boards will then be skipped automatically. |

|

Dispenser System

There are two dispenser system available for BS381N:

DP-2 dispenser system is using computer timing control to dispense solder paste or glue which is very suitable for R & D and making sample.

MT-2 high accuracy dispensing system built in heating & pressure control which are suitable for high accuracy dispensing such as solder pad of QFP (0.4mm pitch ) |

|

Universal CAD Interface

Creating a placement program is one of the most sensitive of tasks.

Each CAD system provides data in a different format.

The universal CAD interface allows a simple and flexible conversion of all CAD Data in ASCII format.

The previously established setup file is used in the conversion to read all assembly steps and to automatically create a pick & place program. |

|

|

Remote Service Kit

Optional Remote Service Kit provide remote access the machine by Internet, so that programming, calibration and service can be done by our worldwide remote service center |

|

Tape Feeder

|

Each smartFEEDER contains a microprocessor, which is in constant touch with the BS381N during production.

This provides the component description or quantity in the feeder.

Setting up for a new feeder arrangement and ensuring that the correct components are present on the machine, is made much easier. |

|

For the feeding of components in tape with the following standard sizes available: 8,12,16,24,32mm.

You can easily replace one individual motor driven feeder without removing a complete feeder rack or set of feeders. |

|

KFTA-08

8mm Auto Tape Feeder for maximum 3.7mm tape thickness |

|

KFTA-12

12mm Auto Tape Feeder for maximum 5.8mm tape thickness |

|

KFTA-16

16mm Auto Tape Feeder for maximum 6.4mm tape thickness |

|

KFTA-24

24mm Auto Tape Feeder for maximum 6.4mm tape thickness |

|

KFTA-32

32mm Auto Tape Feeder for maximum 6.0mm tape thickness |

|

IC Tube Feeder

|

Stick Feeder:

The electronically controlled advance of the feeders ensures that components down to 0603 size can be fed without difficulty.

We use pneumatic feeders for components in tubs.

Individually set feeding steps are possible while requiring very little space.

Use of various adapter plates allow non-standard tube widths to be handled. |

|

| KFTB-2 : 10pcs of 8mm tube |

|

| KFTB-4 : 20pcs of 8mm tube |

|

Special Feeder

| It is recommend that to use ( option ) KFTA-08HS half step feeder for a better performance of picking up 0402.

When using KFTA-08HS, there is no need to select [H]0402 in the library as the feeder is automatic moving in 2 mm pitch, you should select 0402 in library.

For picking up 0201, it must use (option) NZ4-0201 nozzle and KFTA-08HS half step feeder. |

|

KFTA-08HS

8mm Auto Tape Feeder with half step advance suitable for 0201/0402 |

|

Tray

|

QA-1 Waffle Tray

Suitable for different size of IC tray |

|

TS-D16 Bulk Pack Component Tray

Bulk pack component can also be handle under semi-auto production mode. |

|

Cut Scrip Tape Holder

Cut Scrip Tape Holder(TS-CST08-10)

08mm Cut Scrip Tape holder with 10 lane |

|

Cut Scrip Tape Holder(TS-CST12-7)

12mm Cut Scrip Tape holder with 7 lane |

|

Cut Scrip Tape Holder(TS-CST16-6)

16mm Cut Scrip Tape holder with 6 lane |

|

Cut Scrip Tape Holder(TS-CST24-4)

24mm Cut Scrip Tape holder with 4 lane |

|

Cut Scrip Tape Holder Stand(TS-CST-STAND01)

for 8mm,12mm Cut Scrip Tape stand |

|

Cut Scrip Tape Holder Stand(TS-CST-STAND02)

for 16mm,24mm Cut Scrip Tape stand |

|

Feeder Stand(FR-ST64)

Can store 64pcs 8/12mm smart feeder and 38pcs component type |

| |

|

|

|

|

|